Our application and engineering expertise makes us the ideal partner for customer-specific developments, since 1968. In our in-house laboratories, applications can be simulated and optimally tested.

The disciplines motor & bearing technology, airflow, acoustics, fine balancing, electronics as well as measuring and testing technology are among Micronel’s core competencies. We are used to listening to the customer, understanding his task and implementing the best solution together. Prompt, reliable and sustainable. We differentiate between product modifications and fully customized solutions.

are based on our standard products and often concern typical product features or interfaces.

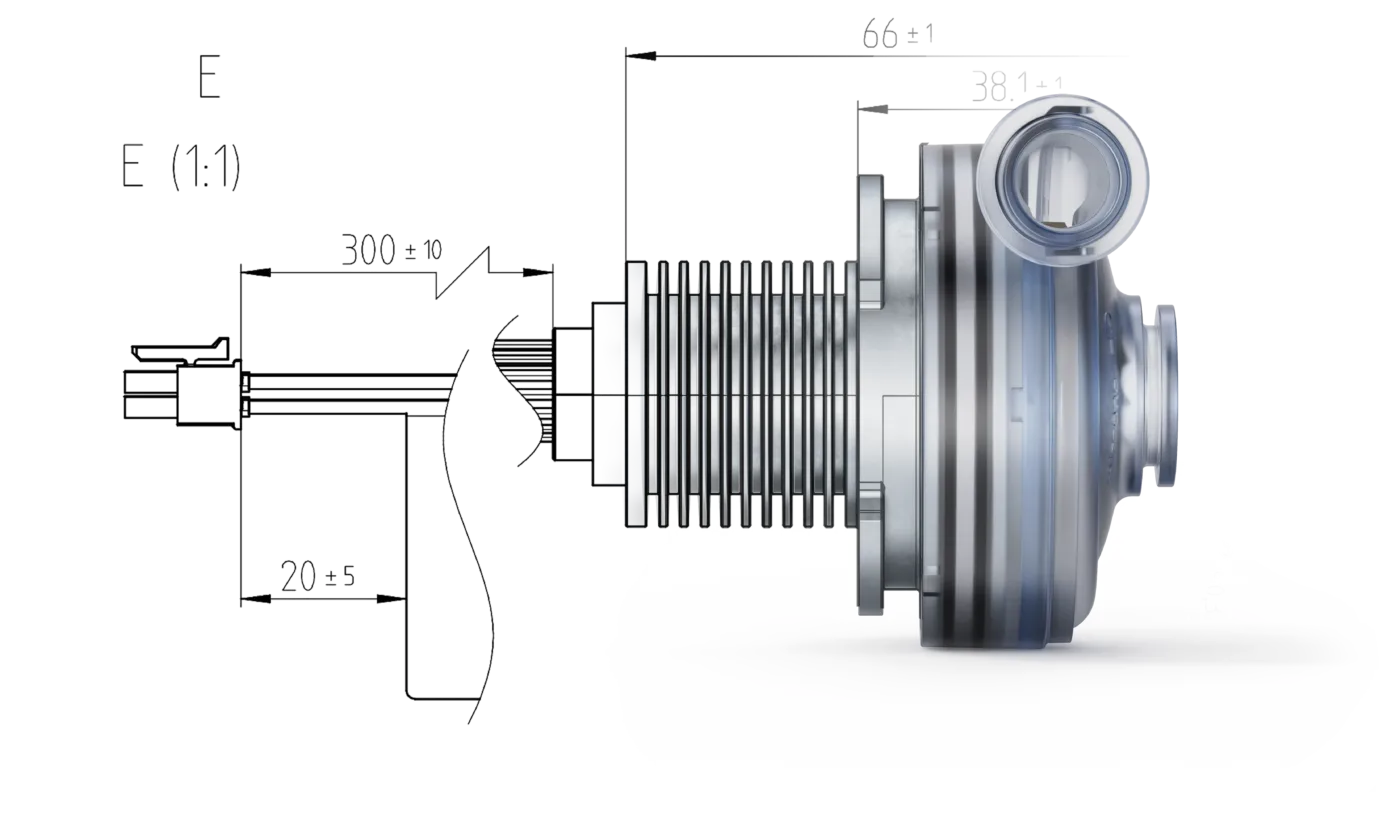

Sealings

Increased IP protection, ATEX or 100% gas tightness are typical individual adaptations

Cables and connectors

We assemble cable lengths, cable types or specific connectors

Motors

If specific operating voltages are required, we modify the windings

Fasteners

Individual fastening solutions are: Clamp, bayonet or screw connections

Electronics optimizations

For approvals, increased safety, specific functions or performance features

Inlet and outlet adapter

Specific geometries, materials or spacers are available for selection

Labels

We meet customer-specific marking and label types with flexible marking

Fan impellers

Geometries and materials for specific pressure/flow characteristics and resistance