Efficient Testing of Micronel Blowers

Mini Smart Driver Module MSDM-24/10 Eval-Kit

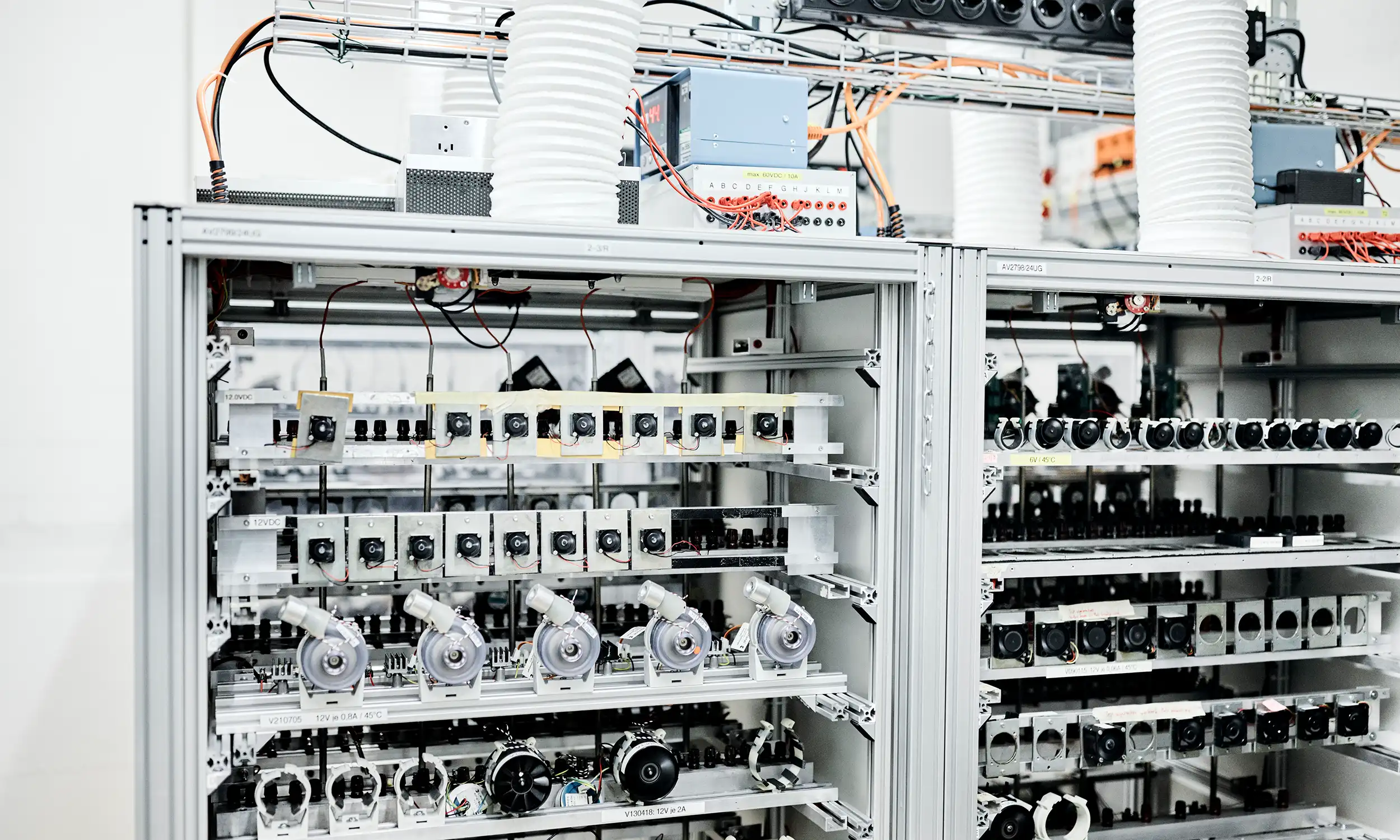

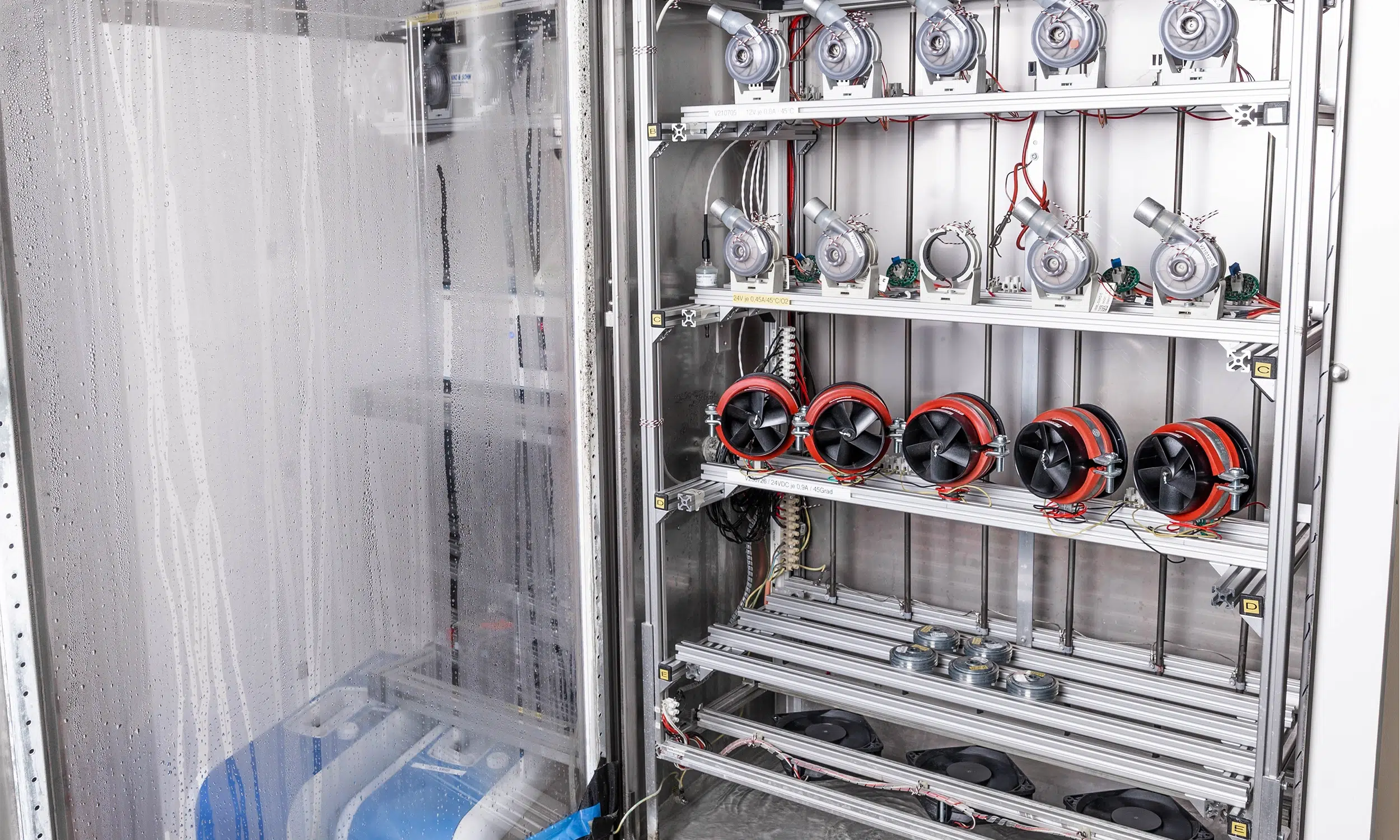

The MSDM Eval Kit is the ideal solution for quickly and easily testing Micronel blowers. Whether for developing new applications or expanding existing systems, this kit allows you to unlock the full potential of a blower. It enables seamless integration and precise control.

Quick Start with Intuitive Operation

The Eval Kit is designed to make the setup of sensorless BLDC blowers as simple as possible.

- Plug & Play: Simply connect and start immediately.

- Flexible Speed Control: Set the speed via potentiometer or PWM input.

- Real-Time Feedback: LED status indicators show the operational state.

The Eval-Kit

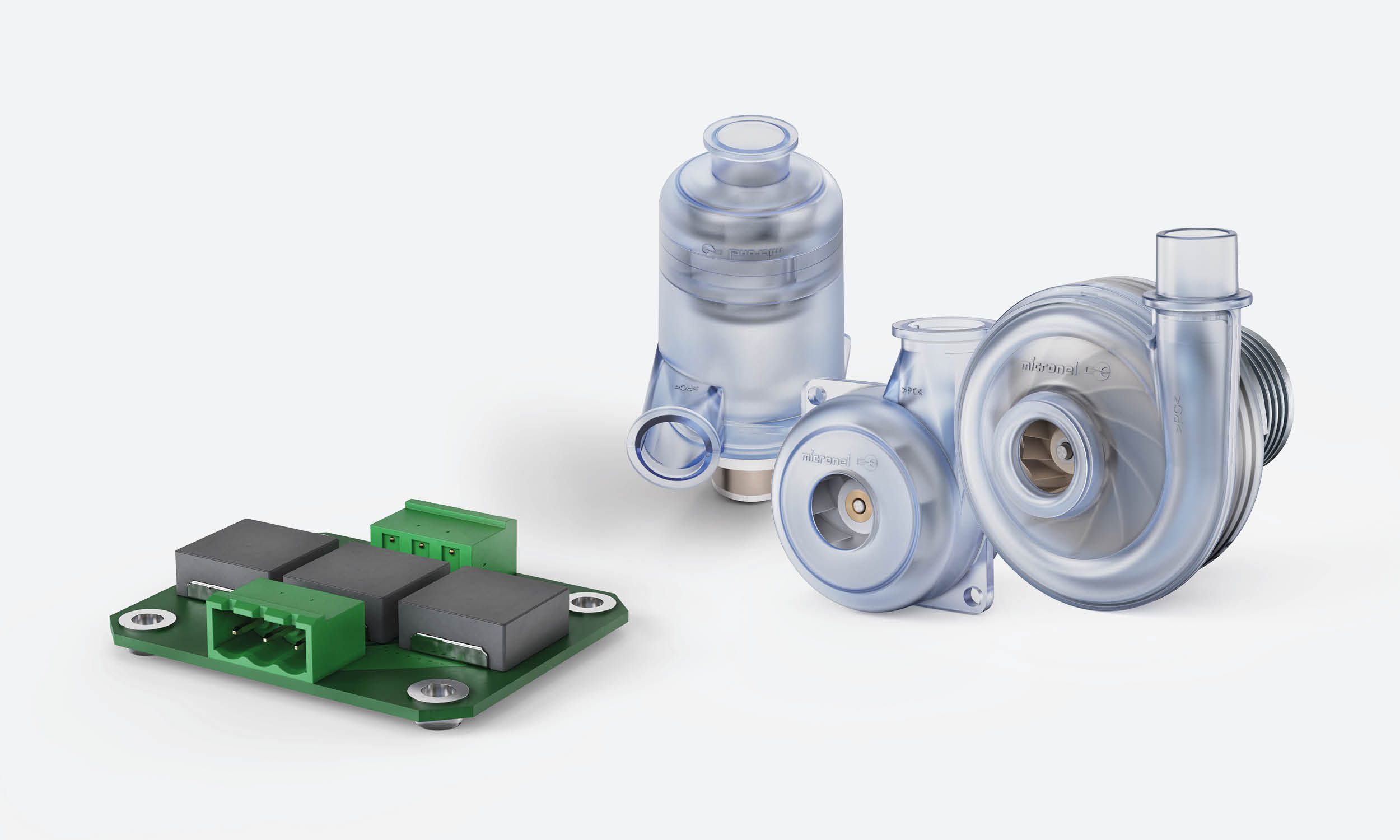

The Mini Smart Driver Module (MSDM-24/10), the core component of the kit, was specifically developed for Micronel blowers and provides a compact, powerful solution for controlling BLDC motors. The Eval Kit is based on the MSDM-24/10. What makes the Eval Kit special is its preconfigured setup and ease of use: it comes pre-assembled with connecting cables for Micronel blowers, a potentiometer for speed control, and switches for configuration, allowing for immediate use.

Perfectly Matched to Micronel Blowers

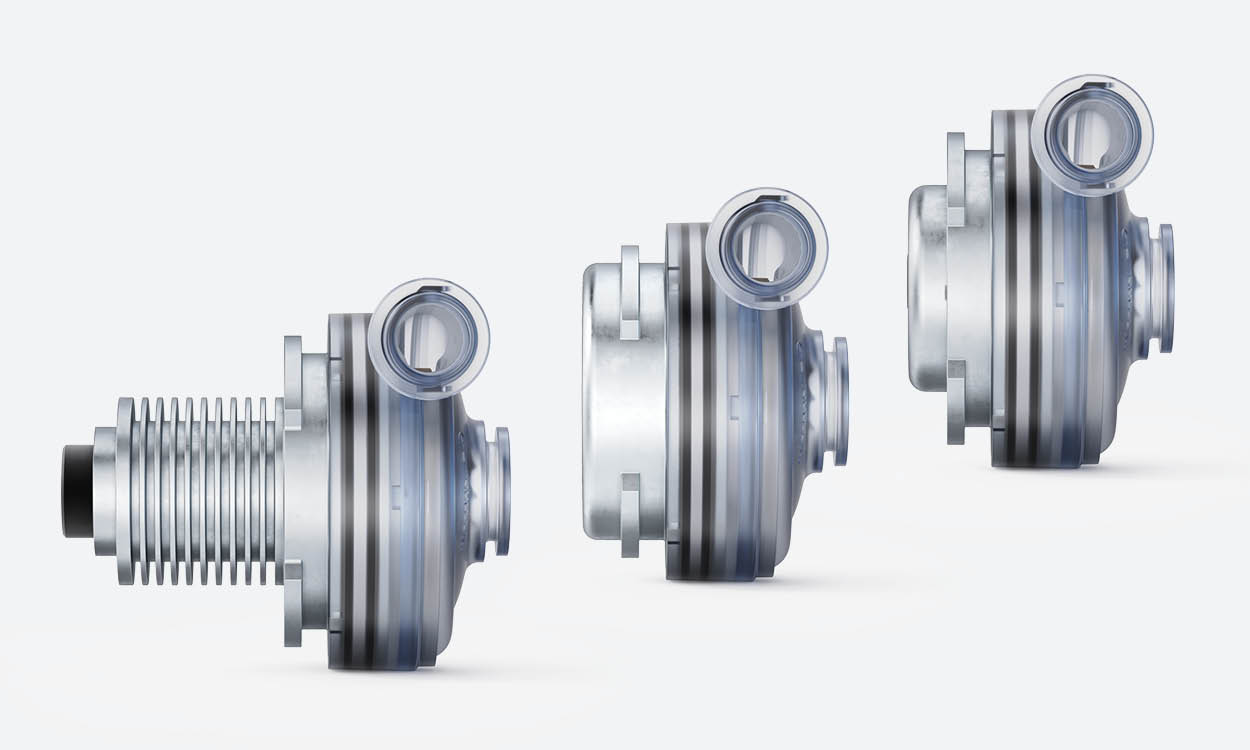

The MSDM Eval Kit is compatible with a range of powerful Micronel radial blowers, including: U51DX-012KK-5, U51DX-024KK-5, U65HN-024KS-6, U65ML-012KS-5, U65ML-024KS-5, U65ML-024KT-5, U65MN-024KS-5, U65H4-024KX-6, U71HL-024KM-5, U71HN-024KX-6, U85HL-024KH-5, U85MX-024KE-5, U85MX-024KX-5, U85MN-024KX-5.

Learn More

For detailed specifications of the MSDM-24/10 Eval Kit, click here or read our article about the core component, the Mini Smart Driver Module-24/10.

Contact us today to streamline your development process with the MSDM Eval Kit!